PVD COATING

SPUTTERING. PRECISE. INDIVIDUAL.

With the PVD (Physical Vapor Deposition) coating process, WIELAND offers the ideal contract coating for your product. Using this technology, it is possible to coat almost all materials with metals or metallic compounds. In addition to electrically conductive substrates, materials such as glass, ceramics, plastics and titanium base materials can also be adhesively coated.

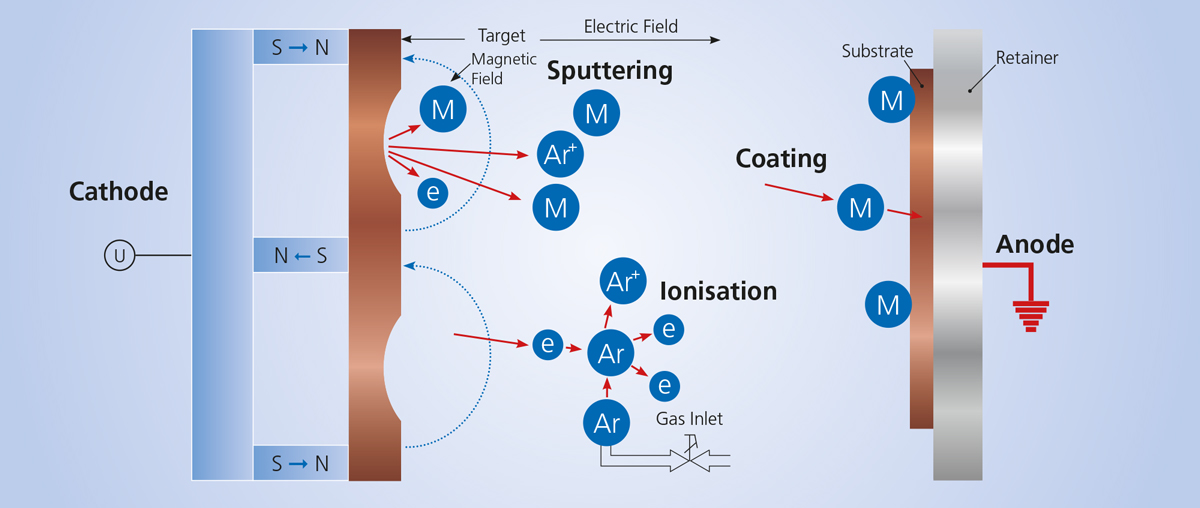

The sputtering technique is used for this purpose, in which the process gas (in this case argon) is ionized by electrons in a high vacuum. The gas is then strongly accelerated as an argon ion in the electric field and impacts on the cathode with the coating material (target). This causes it to atomize and condense on the opposite substrate, building up the layer. Layers of silver, hard and fine gold, palladium, platinum, copper, nickel, chromium and molybdenum can be produced. In addition, non-electroplating materials such as titanium, tungsten and aluminium are also possible coating materials. Typically, layer thicknesses of 0.2 – 5.0 µm can be produced and multilayer systems can also be realised.

In addition to the full-surface finishing of products, individual solutions for selective finishing can also be realised. Even the smallest components (< 1 cm²) as well as parts up to a size of 470 x 470 x 440 mm can be coated. In this context, PVD coating offers an economical method for contract coating even for very small and small batches.

In addition, PVD coating is a very environmentally friendly and resource-saving coating process.

At WIELAND, you benefit from years of experience and know-how. We are trusted by customers from a wide variety of industries, such as medical technology, metrology and aerospace.

We will be happy to answer any questions you may have:

+49 7231 1393-192

pvd@wieland-edelmetalle.de